Advait Infratech Limited is a leading manufacturer of fuel cell systems and an EPC contractor for Green Hydrogen and Green ammonia projects in India. Our state-of-the-art facilities and skilled workforce enable us to produce efficient, cost-effective, and eco-friendly fuel cell systems that

meet international standards. Recently we have signed an MOU with Jiangsu HuaDe Hydrogen Energy Technology Co., Ltd, a renowned technology partner in the fuel cell industry. This collaboration will help us to bring the latest technology to our customers and offer them the best solutions for their energy needs.

In addition to manufacturing fuel cell systems, Advait Infratech Limited is also committed to providing sustainable energy solutions through EPC projects for Green Hydrogen and Green ammonia. We are dedicated to reducing carbon emissions and providing reliable and efficient energy solutions that align with the Indian Government’s vision of achieving net-zero carbon emissions.

Our expertise in fuel cell technology and EPC projects enables us to offer our customers a comprehensive range of solutions for their energy needs. We strive to provide the highest quality products and services, and our commitment to excellence and customer satisfaction drives us to provide you with the best value for your investment.

Ms. Rutvi Sheth

| Technical Specifications | |

| Operating Pressure | MPa (G) |

| Rated Current | A(DC) |

| DC Power consumption | Kwh/(Nm3 H2) |

| DI Water Consumption | L/H |

| KOH Electrolyte Concentration | Wt% |

We are thrilled to announce the opening of AGPL’s state-of-the-art fuel cell manufacturing and assembly unit located at Kadi, Gujarat location.

We, AGPL, a leading player in the renewable energy sector, are thrilled to declare the successful completion and inauguration of a groundbreaking 300 kW Green Hydrogen Production plant and a 70 kWh PEM Fuel Cell at the THDC India Limited (THDCIL) office complex in Rishikesh. This accomplishment marks a significant stride in India’s journey towards sustainable energy solutions and a cleaner, greener future.

Commencing on January 5, 2023, the project has been executed with impressive efficiency, showcasing our steadfast commitment to delivering cutting-edge technology solutions. The inauguration of this hydrogen plant on January 26, 2024, is not only a historic moment for us but also for the region and the renewable energy industry as a whole.

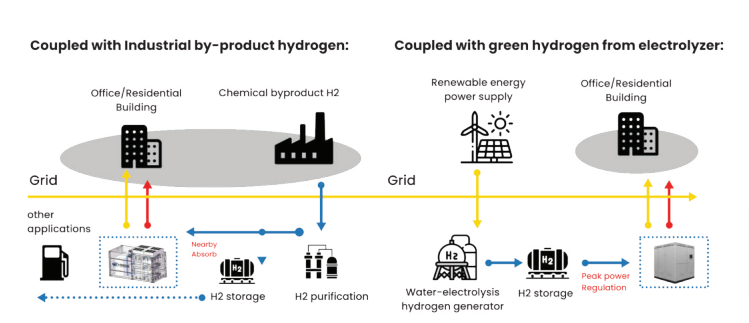

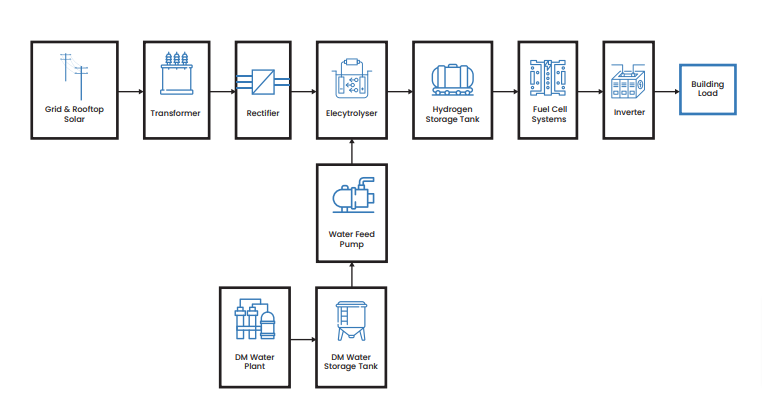

Our pioneering microgrid system incorporates a 300 kWh Alkaline Electrolyser, capable of generating 50 kg of high-purity hydrogen during daylight hours. This hydrogen is stored in a state-of-the-art 24m3 storage tank, pressurized at 30 bar, ensuring its availability when needed. During nighttime, the stored hydrogen seamlessly powers a 70 kWh fuel cell, contributing to THDC’s grid and enhancing a more stable and sustainable power supply.

H2ES Series Fuel cell CHP system consumes natural gas to supply low-carbon emission electrical energy and thermal energy. It integrates a natural gas reformer inside which can convert methane-rich gas to be Hydrogen-rich gas. Through highly efficientelectrochemical reactions, the system can output 5KW power and 7.5KW heat simultaneously. The power generation efficiency can be up to 40% and the overall energy conversion efficiency rate can reach up to 93.5%.

_____________

Up to 40% power generation efficiency and 93.5% overall energy conversion efficiency, much higher than other types of power generation systems or CHP technologies

_____________

The Hydrogen fuel cell system can convert the fluctuating and intermittent solar and wind power into stable and constant energy unaffected by time and the environment.

Fuel cells provide many advantages for India. Some of these are:

Fuel cells produce electricity without combustion, resulting in minimal air pollution and reduced greenhouse gas emissions. Additionally, these cells have an efficiency of up to 60 percent, significantly higher than traditional combustion engines.

Fuel cells offer versatility as they can be applied to various purposes, such as transportation, stationary power generation, and portable electronics.

Fuel cells can use various renewable fuel sources, including hydrogen, methane, and biogas, making them a flexible and sustainable energy

Fuel cells have a long lifespan and require little maintenance, making them a reliable energy source. At the same time, it is also cost-effective.

Project Place: In Jiangsu Science and Technology University

Running Conditions:

Power: 5kw, powering the electrical appliances on grid and surplus fed to the grid Heat: 7.5kw, put hot-water for the public bathroom coupled with gas boiler

Significance:

First commercially applied fuel cell CHP system in China as a bench marking and demonstration example in fuel cell field.

Project Place:

Beijing Daxing Hydrogen Energy Demonstration Park

Running Conditions:

Power: 5kw, to power the air conditioner and the extra electricity is fed to the grid

Heat: 7.5kw, absorbed by radiator systems

Significance:

First fuel cell CHP system pilot project in China The unique Hydrogen product that is actually running in the demonstration park

Project place:

Qinghai Province, China

Running Conditions:

Power: 5kw, to power the electrical appliances Heat: 4.5kw, output in the form of hot-water

Significance:

company's first attempt to transform from "gray Hydrogen' to 'Green Hydrogen’ further strengthens the independent technical control in the integration of modular small- power fuel cell CHP system, low-pressure pure Hydrogen fuel cell stack and

distributed energy management system

We are a global leader in manufacturing tools and infrastructure solutions in telecommunication and power transmission sector

+91 (79) 4895 6677

info@advaitinfra.com

KIFS Corporate House, 1st Floor, Iskcon Ambli Road, Ahmedabad